Research Stories

Green hydrogen production: Restructuring highly electron-deficient metal-metal oxides

Iridium on MoO3 exhibits a low overpotential for oxygen evolution and excellent durability in acidic media due to the high oxidation state of iridium metal on MoO3.

Chemistry

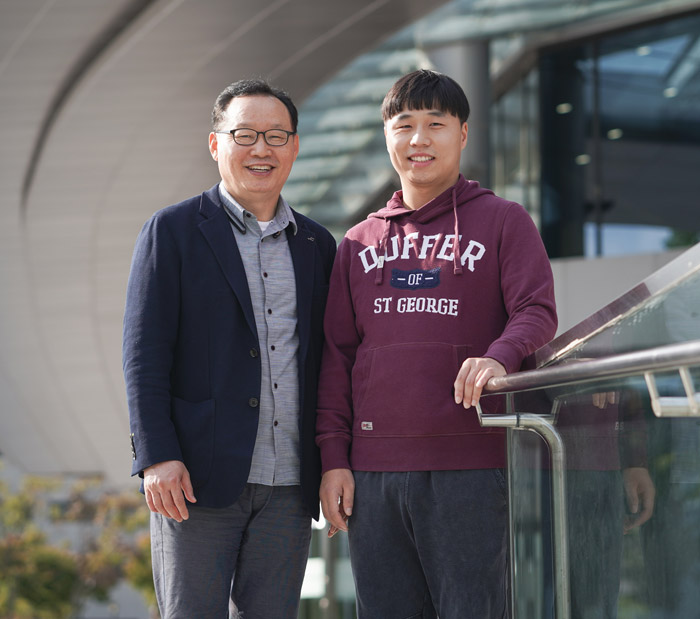

Prof.

LEE, HYOYOUNG

Dr. Liu, Xinghui

While traditional hydrogen production processes require fossil fuels or CO2, electrolysis produces “green hydrogen” from water molecules. Since water cannot be split into hydrogen and oxygen by itself, the electrochemical hydrogen-water conversion needs highly active electrocatalysts. Conventional water electrolysis, however, faces technological challenges to improve the efficiency of the water-splitting reaction for the sluggish oxygen evolution reaction. Though the alkaline water electrolysis technology is dominating the large-scale production of H2, proton exchange membrane (PEM) water electrolysis has clear advantages such as compact configuration, larger maximum current densities, higher energy efficiency, less H2 impurity, and dynamic flexibility of operation. As a half-reaction of water splitting, oxygen evolution reaction (OER) is a major bottleneck due to its sluggish kinetics, while the current OER catalysts typically degrade rapidly under acidic conditions, are not stable in highly oxidative environments, and are of high cost. Thus, developing low-cost and high-efficiency OER catalysts, especially those stable in acidic media, has been a pressing need but remains a grand challenge.

Led by Professor LEE Hyoyoung of Sungkyunkwan University, the research team developed a highly efficient and long-lasting electrocatalyst for OER using iridium and MoO3. “ We introduce electron-deficient metal on semiconducting metal oxides-consisting of Ir-MoO3 embedded by graphitic carbon layers (IMO) using an electrospinning method. To rationally design electron-deficient metal on metal oxides, the electrospinning strategy aid of polyvinylpyrrolidone (PVP) facilitates the different reduction ability of the two metal oxides because their formation energies are -0.862 eV/atom for IrO2 and -1.929 eV/atom for MoO3. PVP was adopted to help reduce the IrO2-only in the air annealing condition (500 °C) to achieve the electron-deficient surface of Ir and to provide graphitic carbon layers from thermal decomposition. The graphitic carbon layer acted as the protective layer to confer high durability and conductivity to facilitate the fast electron transfer during the OER process. IMO nanocomposite can therefore be successfully synthesized via the economical one-pot to create an electron-deficient surface on Ir (Irx+; x > 4) by virtue of two factors: (i) surface oxygen of Ir; (ii) the electron-withdrawing material of MoO3.” says LIU Xinghui the first authors of the study.

“We were very excited to discover that highly electron-deficient metal-metal oxides surface for IMO, demonstrated superior OER activity by evidence of ultra-low overpotential and high stability compared to the benchmark materials of Ir and RuO2 since the synergic effect of high surface state of Ir with the help of the Mo5+ can withstand resistance in an oxidation state,” notes Professor Lee, the corresponding author of the study. The researchers found that the electrospinning synthesized method not only works for metal of Ir-MoO3. The metal metal-metal oxides systems for Rh-MoO3, Au-MoO3, Ru-MoO3 were created, which provides the general strategy-electron-deficient surface of metal on metal oxides driven by surface oxygen and electron-withdrawing groups of the substrate for guiding other metal-semiconductor design.

The research team evaluated the catalytic efficiency with the overvoltage metrics needed for the oxygen evolution reaction. The advanced noble electrocatalyst required only 156 mV (millivolt) overvoltage to attain a current density of 10 mA (milliampere) per cm2 of catalyst, while ruthenium oxide needed 293 mV and Iridium needed 328 mV. In addition, the IMO showed long-term stability for 48 hours without surface change of surface structure. Furthermore, the proton dissociation pathway is suggested via surface oxygen serving as proton acceptors, based on the density functional theory simulation.

▲ The schemic diagram for the OER process using highly electron-deficient iridium metal on metal oxides of MoO3.

Professor explains, “This study suggests high stability with high catalytic performance in these materials by creating electron-deficient surfaces and provides a general, unique strategy for guiding the design of other metal-semiconductor nanocatalysts. This study takes us a step closer to a carbon-free and green hydrogen economy. This highly efficient and inexpensive oxygen generation electrocatalyst will help us overcome long-term challenges of the fossil fuel refining process: to produce high-purity hydrogen for commercial applications at a low price and in an eco-friendly manner.”

The study was published online in the journal Nature Communications.

Notes for editors

- References

Xinghui Liu, Shibo Xi, Hyunwoo Kim, Ashwani Kumar, Jinsun Lee, Jian Wang, Ngoc Quang Tran, Taehun Yang, Xiaodong Shao, Mengfang Liang, Min Gyu Kim, Hyoyoung Lee Restructuring highly electron-deficient metal-metal oxides for boosting stability in acidic oxygen evolution reaction. Nature Communications. doi.org/10.1038/s41467-021-26025-0